TiBrid™ SA Product Features

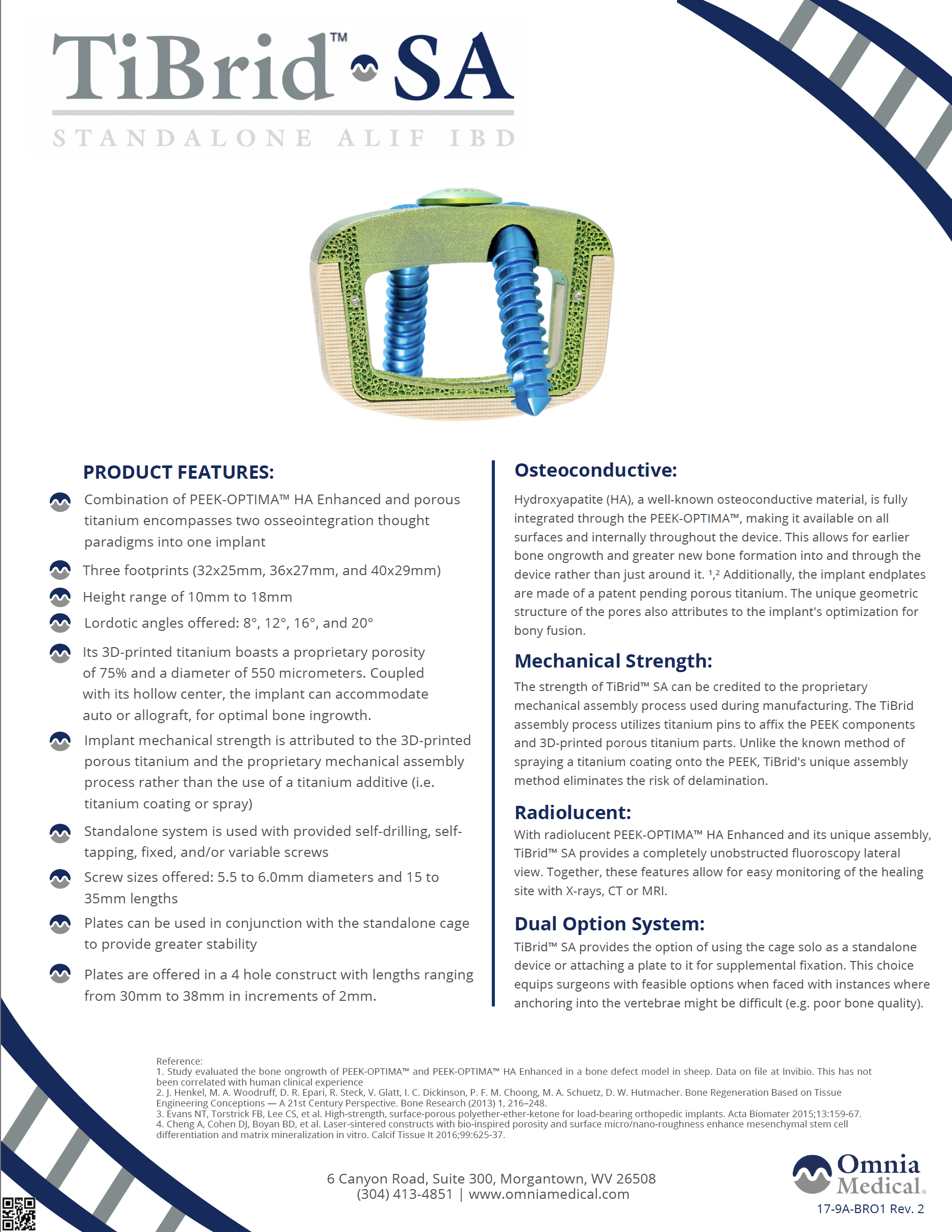

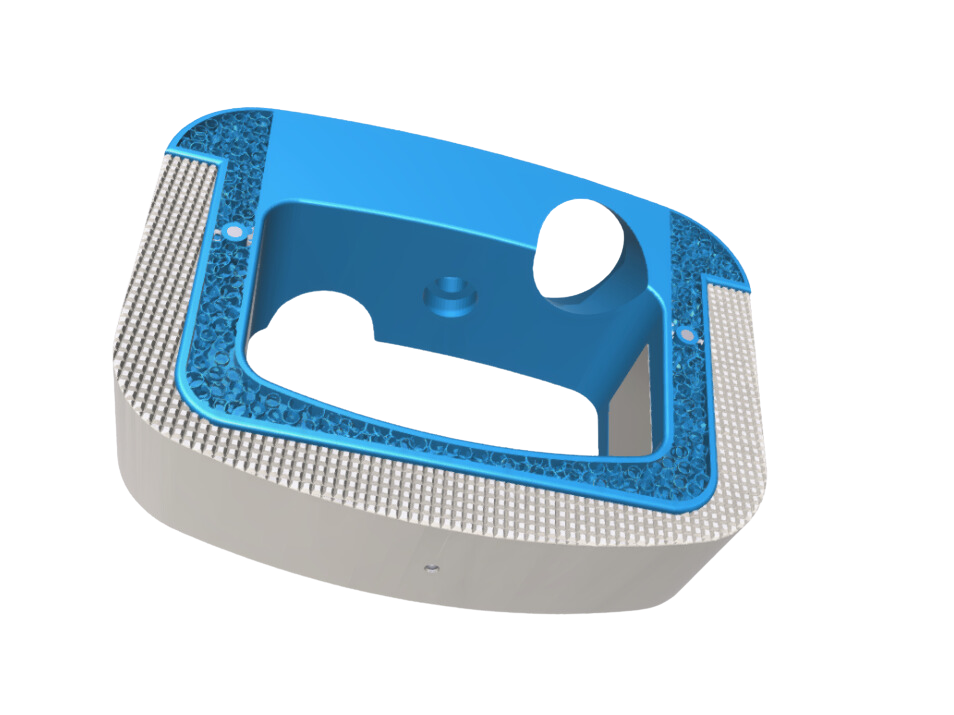

Combination of PEEK-OPTIMA™ HA Enhanced and porous titanium encompasses two osseointegration thought paradigms into one implant

Its 3D-printed titanium boasts a proprietary porosity of 75% and a diameter of 550 micrometers. Coupled with its hollow center, the implant can accommodate auto or allograft, for optimal bone ingrowth.

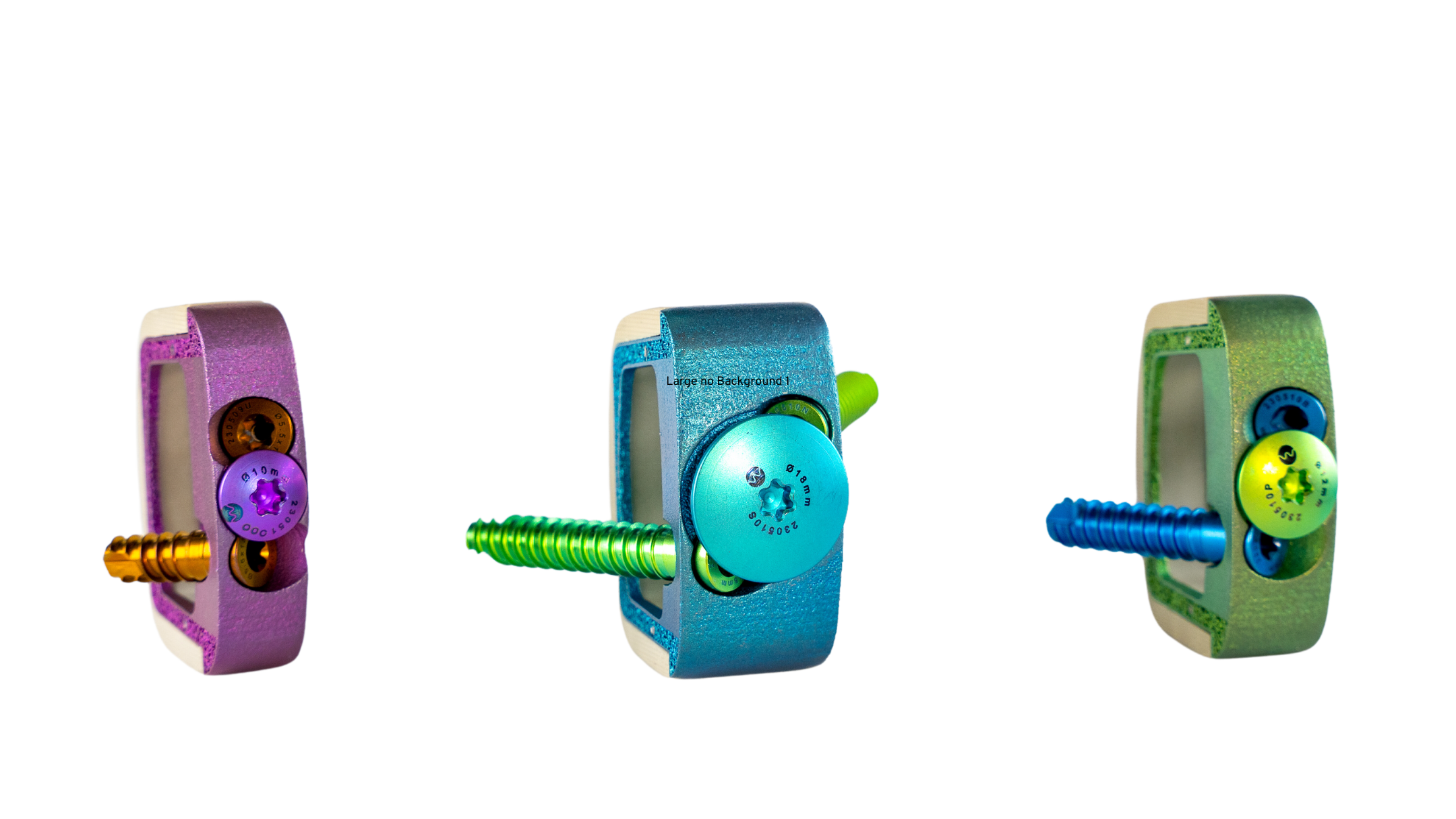

Standalone system is used with provided self-drilling, selftapping, fixed, and/or variable screws

Plates can be used in conjunction with the standalone cage to provide greater stability

Plates are offered in a 4 hole construct with lengths ranging from 30mm to 38mm in increments of 2mm.

Implant mechanical strength is attributed to the 3D-printed porous titanium and the proprietary mechanical assembly process rather than the use of a titanium additive (i.e. titanium coating or spray)

Osteoconductive:

Hydroxyapatite (HA), a well-known osteoconductive material, is fully integrated through the PEEK-OPTIMA™, making it available on all surfaces and internally throughout the device. This allows for earlier bone ongrowth and greater new bone formation into and through the device rather than just around it. Additionally, the implant endplates are made of a patent-pending porous titanium. The unique geometric structure of the pores also attributes to the implant's optimization for bony fusion.

Mechanical Strength:

The strength of TiBrid™ SA can be credited to the proprietary mechanical assembly process used during manufacturing. The TiBrid assembly process utilizes titanium pins to affix the PEEK components and 3D-printed porous titanium parts. Unlike the known method of spraying a titanium coating onto the PEEK, TiBrid's unique assembly method eliminates the risk of delamination.

Radiolucent:

With radiolucent PEEK-OPTIMA™ HA Enhanced and its unique assembly, TiBrid™ SA provides a completely unobstructed fluoroscopy lateral view. Together, these features allow for easy monitoring of the healing site with X-rays, CT, or MRI.

Dual Option System:

TiBrid™ SA provides the option of using the cage solo as a standalone device or attaching a plate to it for supplemental fixation. This choice equips surgeons with feasible options when faced with instances where anchoring into the vertebrae might be difficult (e.g. poor bone quality).